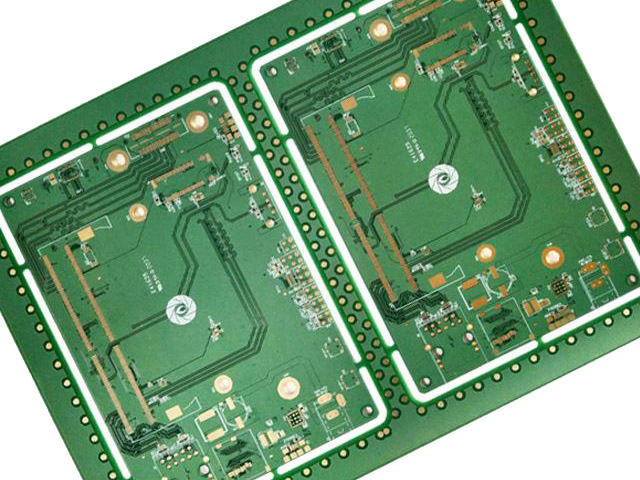

Customers who need to become more familiar with the PCB industry usually find it confusing how much manufacturers charge for their products. It is because manufacturers estimate PCB assembly prices after taking into consideration a variety of factors.

Thus, before approaching a PCB manufacturer with his specs, a customer should thoroughly understand the numerous elements effecting PCB assembly price. It aids the program user in more effective planning and estimating his PCB projects.

PCB cost estimation Elements:

The following factors are accessed by PCB makers when determining a PCB assembly price.

- Board size:

The panel serves as the primary raw material for making PCBs. The ultimate price depends on the total size of the boards used for a particular PCB project. Therefore, the initial cost will increase with the size of the panel.

- Lead Time:

When determining the cost of PCB manufacture and assembly, time leading is a vital component to consider. Projects that must be finished with a shorter lead time will cost more money.

- Layers:

Manufacturing single-sided and double-sided PCBs involves comparable costs. However, creating multi-layered PCBs will cost you more money because it requires several complex manufacturing steps and acquiring additional raw materials.

- Examination Fees:

The completed PCBs undergo a rigorous quality inspection process to guarantee the unit’s quality and electrical performance.

Manufacturers may test a device for impedance, ionic compatibility, and other factors before shipping it to end users, in addition to electrical testing. As a result, the project’s cost may increase by 10% to 15% due to these inspections.

- Surface Quality:

The PCB application regions are hostile. Hence the boards are shielded with corrosion-resistant surface treatments. In addition, options for highly specialized surface treatment, coating, and painting are available to increase the PCB assembly’s robustness.

Upon request, several gold and silver treatments are available to manufacturers to obtain increased protection for use in demanding industrial applications. Depending on the surface finish you select, the PCB assembly price varies.

- Drill Size and Counts:

The size and quantity of drill holes play a crucial role in cost determination during PCB manufacture. Drilling small holes, less than 0.012 inches in diameter, is more expensive for applications that call for it. The rationale is drilling intricate holes may need sophisticated laser drilling procedures. To drill more holes of smaller diameters, manufacturers need to modify their manufacturing procedures and techniques, which might increase project costs by 10% to 20%.

- Dimensions of Raw Materials:

PCBs are made from various materials, exhibiting high wear, tear, and corrosion resistance levels. The production process uses multiple materials, including copper foil, polyimide, and fiberglass.

The fabricator needs more raw materials to create a multi-layered PCB assembly than a single-layered PCB. For smaller, thinner boards, a similar set of parts is required. More minor things cost substantially more than larger, bulkier products.

The tooling equipment needed to handle such components will likewise need to be more precise. The kind and size of raw materials, as a result, significantly impact the final PCB assembly price.

- Filling vias:

The PCBs typically have partially filled vias. However, some customers require that the vias be filled for specific projects. The fabricator completes the task using specialist non-conductive or conductive material in these circumstances. This procedure will increase the PCB’s assembly price by at least 10%.

- Add-ons:

Some projects require specific fabrication on the usual circuit board. In addition, customers may have special requirements, such as the necessity for final assemblies to have regulated depth drilling, counter-bores, and counter-sinks, as well as sophisticated routing. These processes require additional production steps, high-level expertise, and state-of-the-art tools. This different fabrication will result in a 5%–10% price increase or higher for the PCB.

Conclusion:

The features listed above are a few that a manufacturer considers when creating the PCB quotation to estimate PCB assembly price. After reading this article, customers familiar with the typical cost-estimating elements can better grasp cost adders. For good measure, if you are worried about price, Eashub has got your back by providing qualitative yet the most affordable PCB assembly services.