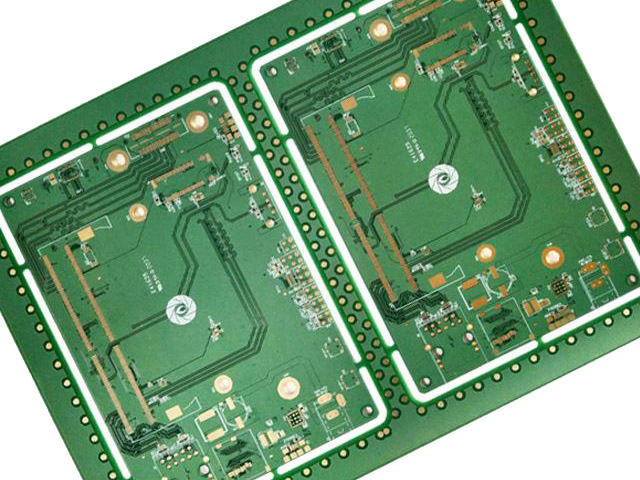

Printed circuit boards (PCBs) are an integral part of electronic devices. They serve as the foundation for electronic components and provide a means for connecting them. There are several types of PCBs available, each with its own set of advantages and disadvantages. In this post, we will be discussing four of the most common types of PCBs: FR4, Aluminum, Copper, and Ceramic.

FR4 PCB

FR4 is a type of PCB material that is made from a combination of glass fibers and epoxy resin. It is the most commonly used type of PCB material and is known for its good mechanical properties and low cost.

Characteristics

- FR4 PCBs have a dielectric constant of around 4.5 and a loss tangent of around 0.02.

- They have a high mechanical strength and can withstand high temperatures.

- They are also flame resistant and have good chemical resistance.

Advantages

- Low cost

- Good mechanical properties

- High temperature resistance

- Flame resistance

- Good chemical resistance

Disadvantages

- Not suitable for high-frequency applications

- Can be brittle

Applications

- Power supplies

- Control systems

- Audio equipment

Aluminum PCB

Aluminum PCBs are made from aluminum-based substrate material. They are known for their excellent thermal conductivity and are often used in high-power electronic devices.

Characteristics

- Aluminum PCBs have a thermal conductivity of around 220 W/m-K.

- They have a low coefficient of thermal expansion.

- They are also lightweight and have good mechanical strength.

Advantages

- Excellent thermal conductivity

- Low coefficient of thermal expansion

- Lightweight

- Good mechanical strength

Disadvantages

- Higher cost compared to FR4 PCBs

- Not suitable for high-frequency applications

- Can be brittle

Applications

- High-power electronic devices

- LED lighting

- Power supplies

Copper PCB

Copper PCBs are made from copper-based substrate material. They are known for their excellent electrical conductivity and are often used in high-frequency electronic devices.

Characteristics

- Copper PCBs have a high electrical conductivity.

- They are also lightweight and have good mechanical strength.

Advantages

- High electrical conductivity

- Lightweight

- Good mechanical strength

Disadvantages

- Higher cost compared to FR4 PCBs

- Not suitable for high-temperature applications

- Can be brittle

Applications

- High-frequency electronic devices

- RF circuits

- Power amplifiers

Ceramic PCB

Ceramic PCBs are made from ceramic-based substrate material. They are known for their excellent thermal conductivity and are often used in high-temperature electronic devices.

Characteristics

- Ceramic PCBs have a high thermal conductivity.

- They have a low coefficient of thermal expansion.

- They also have good mechanical strength and can withstand high temperatures.

Advantages

- High thermal conductivity

- Low coefficient of thermal expansion

- Good mechanical strength

- High temperature resistance

Disadvantages

- Higher cost compared to FR4 PCBs

- Not suitable for high-frequency applications

- Can be brittle

Applications

- High-temperature electronic devices

- Power supplies

- Control systems

Comparison of FR4 PCB, Aluminum PCB, Copper PCB, and Ceramic PCB

When choosing a PCB for a specific application, it is important to consider the properties, advantages and disadvantages, and potential applications of each type.

In terms of properties, FR4 PCBs have a dielectric constant of around 4.5 and a loss tangent of around 0.02. They have a high mechanical strength and can withstand high temperatures. Aluminum PCBs have a thermal conductivity of around 220 W/m-K and a low coefficient of thermal expansion. Copper PCBs have a high electrical conductivity and Ceramic PCBs have a high thermal conductivity and a low coefficient of thermal expansion.

In terms of advantages, FR4 PCBs have a low cost and good mechanical properties, Aluminum PCBs have excellent thermal conductivity and a low coefficient of thermal expansion, Copper PCBs have high electrical conductivity, and Ceramic PCBs have high thermal conductivity and good mechanical strength.

In terms of disadvantages, all of them can be brittle and not suitable for high-frequency applications. Aluminum and Copper PCBs have higher costs compared to FR4 PCBs and Copper PCBs are not suitable for high-temperature applications.

In terms of applications, FR4 PCBs are commonly used in power supplies, control systems, and audio equipment. Aluminum PCBs are commonly used in high-power electronic devices and LED lighting. Copper PCBs are commonly used in high-frequency electronic devices, RF circuits, and power amplifiers. Ceramic PCBs are commonly used in high-temperature electronic devices, power supplies, and control systems.

Conclusion

In conclusion, each type of PCB has its own set of properties, advantages, and disadvantages. The choice of PCB will depend on the specific requirements of the application. FR4 PCBs are a good all-around choice for most electronic devices because of their low cost and good mechanical properties. Aluminum PCBs are a good choice for high-power electronic devices due to their excellent thermal conductivity. Copper PCBs are a good choice for high-frequency electronic devices because of their high electrical conductivity. Ceramic PCBs are a good choice for high-temperature electronic devices because of their high thermal conductivity and good mechanical strength.